On Exchange Engine Parts Concept

Risks of common engine maintenance practices

The downside is that the process above lasts from a couple of weeks and up to 4 or more weeks. Of course, many factors, like unforeseen reconditioning works, lack of parts availability, etc., can contribute to a prolonged maintenance period.

The bottom line is: your engine is down.

Risks of common engine maintenance practices

- In the case of a propulsion engine, the vessel cannot sail at all, costing operators time and money.

- In the case of a Genset on-board, the vessel’s operation is seriously impaired and limited.

- In an engine driving process machinery, a whole production line can stay out of operation until the engine is up again.

- In the case of gensets running in powerplants providing power to communities, uptime is critical and the consequences of prolonged downtime go beyond the financials.

How it works

Allow us to break the procedure down for you.

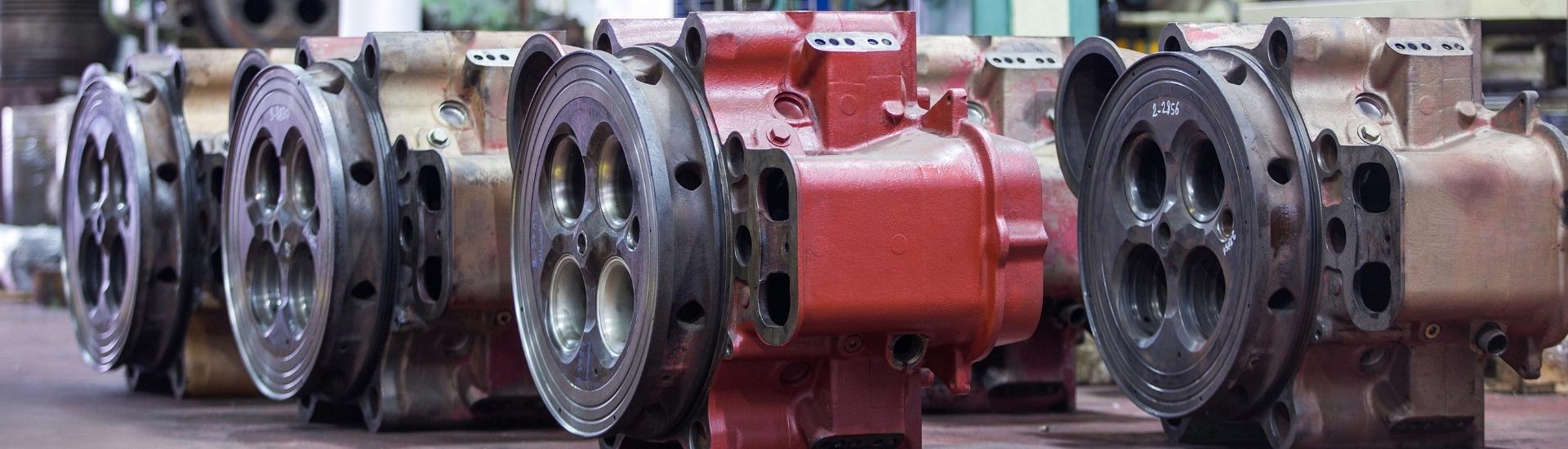

In simple terms, our company sends to the vessel or power plant reconditioned, tested, and ready-to-use parts before the engine overhaul begins and are fitted on the engine immediately.

Then, after being removed from the engine, the old spare parts are returned to our workshop facilities. Components are reconditioned, tested, placed in stock, and made available for the next customer on zero notice.

Benefits of the On-Exchange Engine Parts agreement

- Significant reduction of the maintenance period.

- Fixed costs, budgeting made easy.

- Immediate availability of parts inspected and tested thoroughly.

- Participation in the circular economy by giving old parts a new life!

- Reduction of risk and uncertainty for the duration of an overhaul.

- Reduced costs from the minimum need of expert staff onboard / on-site.

List of spare parts immediately available right from our stock

Two-stroke engine components

- Cylinder heads

- Piston crowns and skirts

- Piston Rods

- Exhaust Valves

- Exhaust valve seats

Four-stroke engine components

- Cylinder heads complete

- Connecting rods

- Pistons

- Liners

- Fuel pumps

- Speed governors